Views: 25 Author: Site Editor Publish Time: 2023-06-15 Origin: Site

In modern agriculture, farmers rely on various tools and techniques to optimize their operations and improve productivity. One such tool that has gained popularity in recent years is the inter-row tiller. This article aims to provide a comprehensive understanding of the inter-row tiller, its functions, benefits, and its impact on farming practices.

An inter-row tiller is a specialized agricultural implement used for soil cultivation and weed control in row-crop farming. It is designed to work in the space between rows of crops, effectively tilling the soil and managing weeds without disturbing the crop plants. The inter-row tiller plays a crucial role in promoting healthy crop growth and maximizing yield.

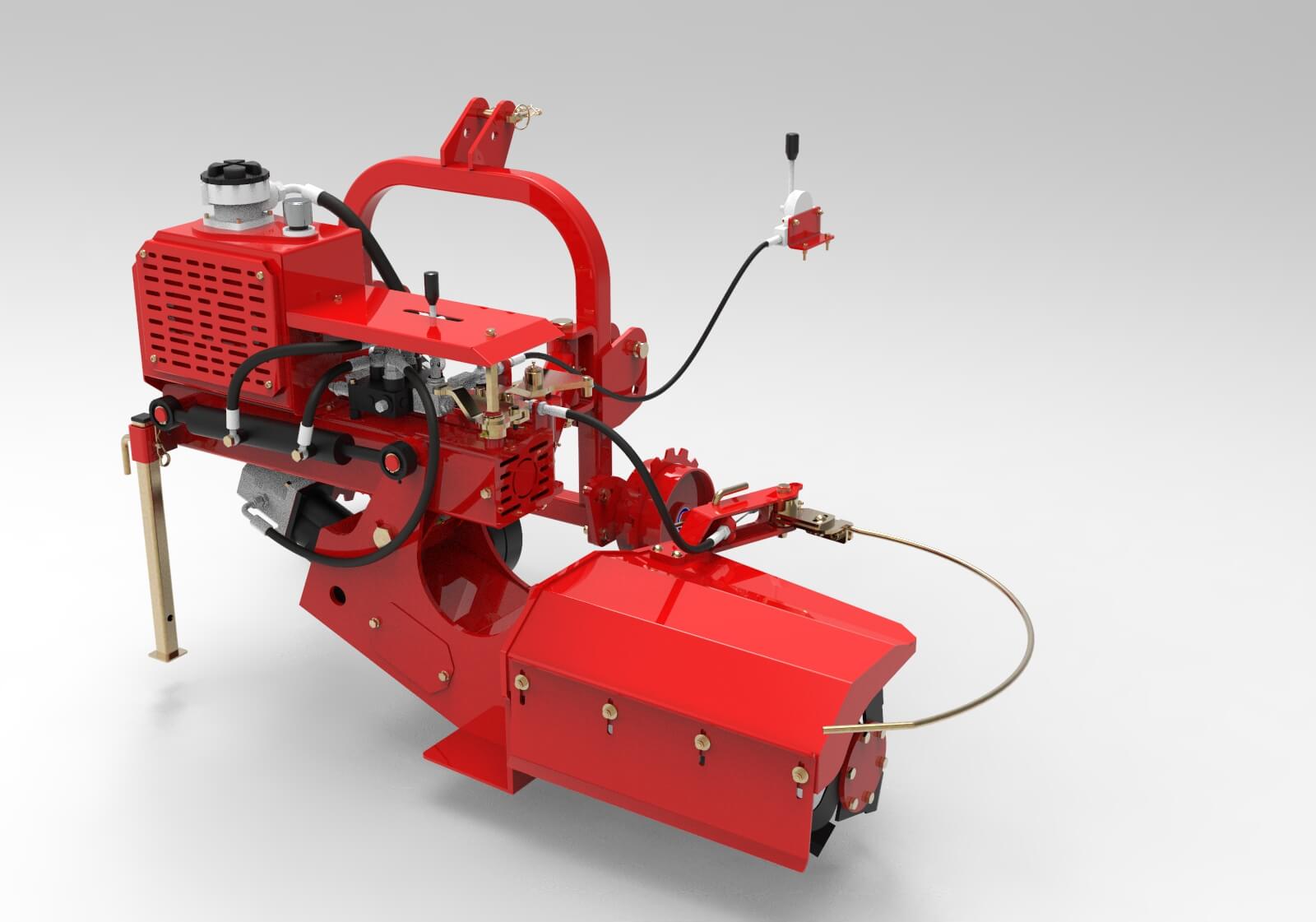

Aiemery inter-row orchard tiller is a specific farming tool created for cultivating soil in orchards. Its purpose is to effectively manage the spaces between tree rows, offering a controlled and efficient approach to controlling weeds and aerating the soil. By tending to the soil in these inter-row areas, the orchard tiller promotes a favorable environment for the roots of the trees and enhances the overall health of the orchard.

An inter-row tiller operates by using rotating blades or tines to cultivate the soil in the inter-row spaces. It is typically attached to a tractor or other farming equipment and can be adjusted to the desired depth and width. As the tiller moves through the field, the blades penetrate the soil, breaking up compacted layers and uprooting weeds. This process helps improve soil aeration, nutrient distribution, and moisture retention.

By using an inter row tiller, farmers can save considerable time and effort compared to manual weeding and soil preparation methods. The mechanized nature of the tiller enables rapid and efficient processing of large areas, resulting in increased overall farm productivity.

Weeds compete with crops for resources such as water, sunlight, and nutrients. Inter row tillers effectively disrupt weed growth by uprooting them from the soil, minimizing their impact on crop yield. This reduces the need for chemical herbicides and promotes more sustainable farming practices.

The action of an inter row tiller improves soil structure and porosity, allowing better water infiltration and root development. The tilling process also helps in breaking up compacted soil layers, enabling proper root growth and nutrient absorption by crops. Additionally, the incorporation of organic matter enhances soil fertility and microbial activity.

Inter row tillers assist in preventing soil erosion by breaking up surface crusts and improving water absorption. By minimizing erosion, farmers can retain valuable topsoil, which is essential for healthy plant growth and long-term sustainability.

There are various types of inter row tillers available in the market, each suited for different farming needs and equipment compatibility.

Mechanical tillers are driven by a power source, such as a tractor or a dedicated engine. They are versatile and widely used in various agricultural applications. Mechanical tillers can be mounted at the front or rear of the tractor, depending on the farming operation and the desired tillage configuration.

Hydraulic tillers are powered by hydraulic systems and are commonly used in orchards and vineyards. They offer precise control and maneuverability, allowing farmers to navigate between closely spaced rows with ease. Hydraulic inter row tillers are often attached to specialized agricultural machinery designed for specific crops and row spacing.

Power Take-Off (PTO) tillers are powered by the PTO shaft of a tractor. They are highly efficient and provide consistent power transmission to the tiller blades. PTO tillers are suitable for larger-scale farming operations where tractors with sufficient power are available.

When selecting an inter row tiller, several factors should be taken into account to ensure optimal performance and compatibility with specific farming requirements.

The size of the farming operation influences the choice of inter row tiller. Small-scale farmers may opt for compact and lightweight models, while larger farms require heavy-duty tillers capable of covering extensive areas efficiently.

Different crops have varying row spacing and root structures. It is crucial to select an inter row tiller that can be adjusted to match the specific crop requirements. Some tillers offer interchangeable blades and tines to accommodate various crop types.

Soil types and conditions vary across different regions. The tiller should be capable of working effectively in the

specific soil composition and moisture levels prevalent in the farming area. Factors such as soil hardness, clay content, and rock presence should be considered when choosing the appropriate tiller.

Inter row tillers can be attached to various agricultural machinery, such as tractors or specialized cultivators. It is essential to ensure compatibility between the tiller and the equipment it will be mounted on to avoid any compatibility issues during operation.

Proper maintenance and care are essential to keep the inter row tiller in optimal condition and prolong its lifespan. Here are some key maintenance practices to follow:

After each use, clean the tiller thoroughly to remove any debris or soil residue. Lubricate the moving parts, such as bearings and joints, to prevent rust and ensure smooth operation.

Sharp blades are crucial for effective tillage. Regularly inspect the blades and sharpen or replace them as necessary to maintain optimal performance. Dull blades can result in inefficient tilling and increased power consumption.

When the tiller is not in use, store it in a clean and dry environment, preferably indoors. Protect the tiller from harsh weather conditions, direct sunlight, and potential damage by covering it or using a suitable storage solution.

To maximize the benefits of an inter row tiller, consider the following tips for efficient and effective usage:

The tiller's depth and width should be adjusted according to the crop's requirements and field conditions. Shallow tilling is suitable for surface weed control, while deeper tilling promotes better soil aeration and root development.

Maintain a consistent operating speed while using the tiller. Excessive speed may lead to inadequate tilling, while slow speeds can cause excessive soil disturbance and increased fuel consumption.

Always prioritize safety when operating an inter row tiller. Wear appropriate protective gear, such as gloves and safety glasses. Familiarize yourself with the tiller's safety features and ensure they are functioning correctly.

Despite their efficiency, inter row tillers can encounter certain challenges. Here are some common issues and troubleshooting tips:

If the tiller blades become clogged with debris or weeds, stop the operation and clear the blockage carefully. Remove any accumulated material and ensure the blades are clean before resuming tilling.

Uneven tilling can occur due to incorrect tiller adjustment or uneven ground surfaces. Double-check the tiller's settings and make necessary adjustments. If the ground is uneven, consider smoothing it out before tilling.

In case of mechanical failures, such as belt slippage or gearbox issues, consult the tiller's user manual or contact the inter row tiller's manufacturer for guidance. Regular maintenance and periodic inspections can help prevent mechanical failures.

The inter row tiller is an invaluable tool in modern agriculture, providing efficient weed control and soil preparation between crop rows. By utilizing inter row tillers, farmers can save time, enhance productivity, and promote sustainable farming practices. Understanding the different types, maintenance requirements, and best practices for inter row tiller usage is key to reaping the benefits it offers.

Aiemery as the inter row tiller's manufacturer, now has two types of inter row orchard tillers , if you want to know more about our products you can always contact us.

Yes, inter row tillers can be used in various crop types, provided that the tiller is adjustable to match the specific row spacing and crop requirements.

The lifespan of an inter row tiller depends on various factors, such as the quality of the tiller, frequency of use, and maintenance practices. With proper care, a well-maintained tiller can last for many years.

The tiller's depth should be set to a level that effectively controls weeds while minimizing disturbance to the crop's root system. Typically, a depth of 2-3 inches is recommended, but it may vary depending on the crop and soil conditions.

Yes, inter-row tillers can be used in organic farming as a mechanical weed control method. However, it's important to ensure that the tiller does not cause excessive soil disturbance or harm the beneficial organisms present in the soil.

Inter row tillers can be purchased from agricultural equipment suppliers, farm machinery dealerships, or online marketplaces specializing in agricultural tools and machinery.